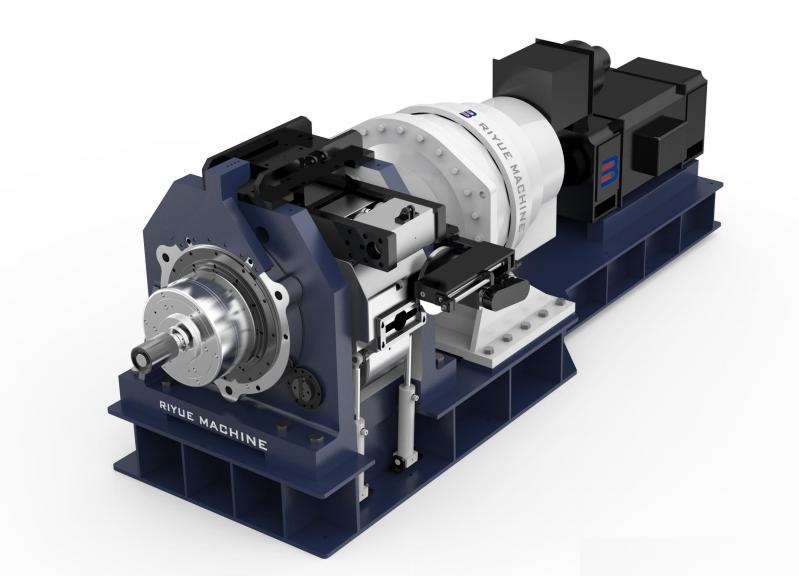

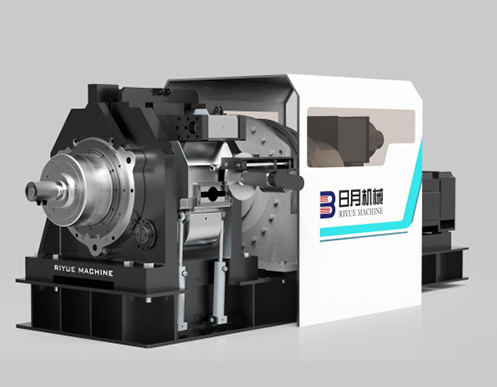

Product Detail

Main Technical Parameters | LLJ300 | LLJ350 | LLJ400 |

Extrusion wheel nominal diameter | 300mm | 350mm | 400mm |

Main motor power | 90kW | 180kW | 250kW |

Installed power | 22.5 m/rpm | 16m/rpm | 4-12.5m/rpm |

Extrusion machine speed | Pure aluminum, aluminum alloy | Pure aluminum, aluminum alloy | Pure aluminum, aluminum alloy |

Types of materials | F9.5/12mm | F15mm | Ø20mm |

rod diameter | 5-150mm2 | 10-600mm2 | 200-1800 mm2 |

Product scope of section | Flat wire, flat tube maximum 30 mm wide, round bar, pipe diameter 20 mm | Flat wire, flat tube maximum 60 mm wide, round bar, pipe diameter 30 mm | Flat wire, flat tube maximum 170 mm wide, round bar, pipe diameter 80 mm |

Product maximum width |

Average productivity | 230kg/h | 450kg/h | 500kg/h |

Material overflow rate | 0 | 0 | 1-3% |

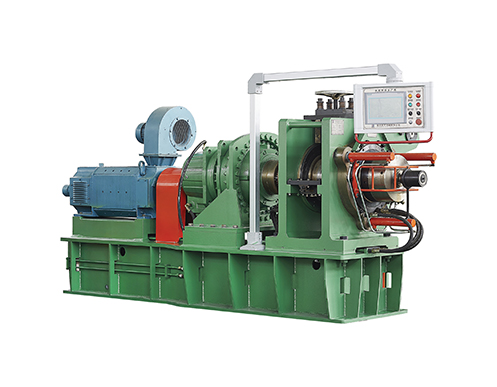

Application:

round tubes of air conditioner and refrigerator, multi-hole tubes for car air conditioner and intercooler, flat aluminum wire, producing pure aluminum L0-L6 and aluminum alloy such as LD31,LF21 and so on

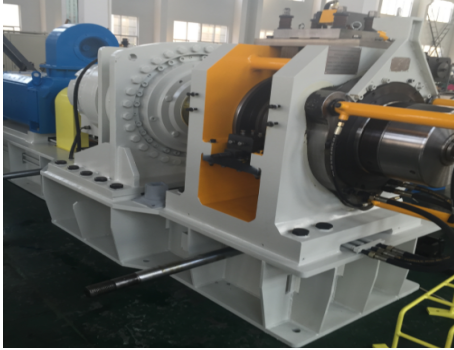

Advantage:

advanced cleaning technology, High precision, advanced mold, low flash rate, New type lining device, convenient handling, Computer intelligent controlling system

LLJ300-Aluminum Continuous Extrusion Machine uses pure aluminum L0-L6 and aluminum alloy such as LD31,LF21 and so on. Advanced cleaning technology is adopted to ensure the cleanness of the stock rod. The stock wire is first given out from pay-off stand, then straightened and cleaning system, then sent to the continuous extrusion host machine for extruding. Wire product form after extruding,then pass through oxidation preventive equipment and cooling system, the last step is wrap-up or length fixed cutting after measured by meter counter and other equipment.

Aluminum Continuous Extrusion Machine, Find complete details about aluminum Continuous extrusion equipment from Changzhou Riyue Machinery Co. Ltd.. You may also find other aluminum extrusion machine products from our website!