Product Detail

Operating principle:

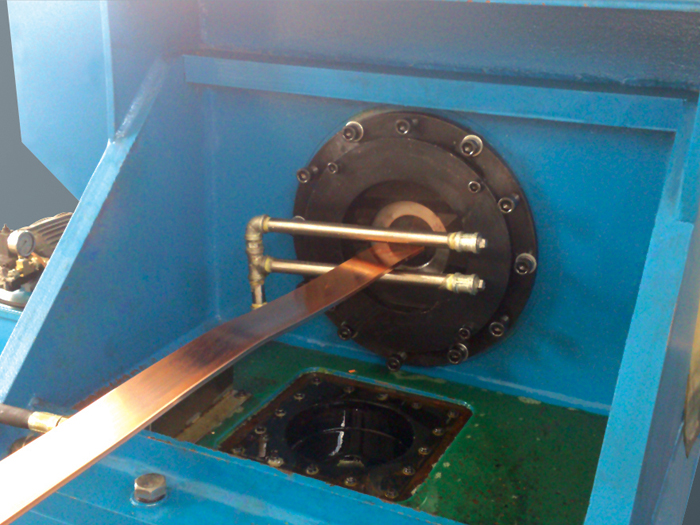

The mchine can be drawing of copper bars, copper rod and other materials .

Finished products can achieve the goals of higher accuracy, brighter surface, greater hardness and elasticity and difficult deformation.

Process flow :

head making → unreeling →straighten→ drawing → saw cutting →movement → tensioning and straightening → lateral movement

→ roll conveying → saw cutting with fixed length →storage

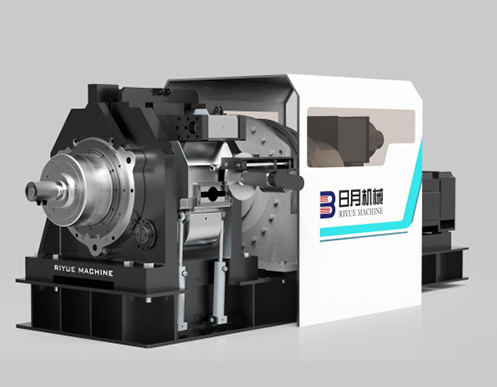

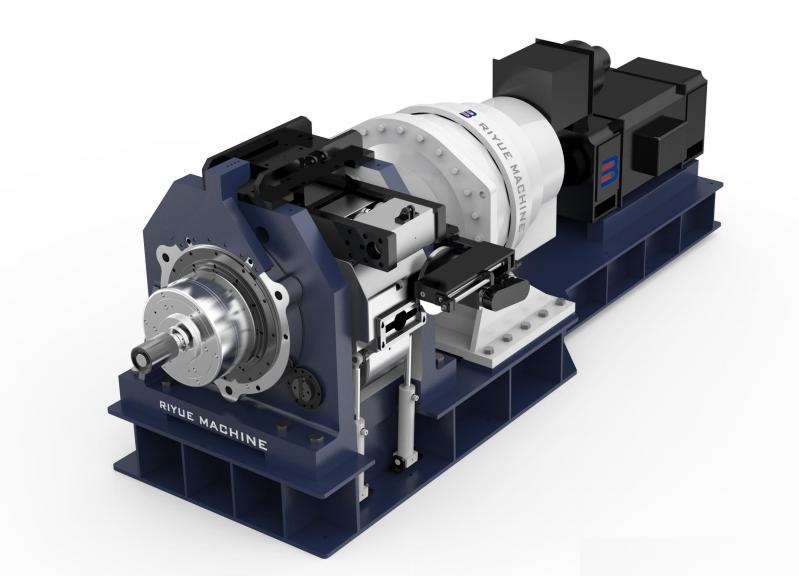

Specification of YLB-50T Hydraulic Automatic Drawing Machine:

Type: YLB-50T

Nominal drawing force(t): 50

Effective drawing length (m): 6/8/10/12

Material size(mm): width≤170,thickness3~30

Drawing speed (m/min): 1~10

Return speed (m/min): 10~48

ID of the cylinder (mm): 220

Diameter of the piston rod (min): 125

Oil pressure from the hydraulic station (MPa): 21

Power supply: Three-phase four-wire system,380V/50HZ

Capacity (kW): 75/75/88/90

Weight of the equipment(t): 20/23/27/32

Device Configuration:

No. | Configuration Names | Qty | Remarks |

1 | Copper Rod Rack | 1 PC |

|

2 | Straightening Feeder | 1 PC |

|

3 | Drawing Mainframe | 1 PC |

|

4 | Hydraulic Device | 1 SET |

|

5 | Circulating Cooling system | 1 SET |

|

6 | Blanking Cutting Mechanism | 1 SET |

|

7 | Transfer Mechanism | 1 SET | 6 |

8 | Plane Transfer Roll Table | 1 SET | 6 m |

9 | Finished Product Fixed-Length Cutter | 1 SET |

|

10 | Finished Product Cutting Platform | 1 SET | 4 m |

11 | Finished Product Stacking System | 1 SET |

|

12 | Electrical Control System | 1 SET |

|

13 | Copper-bar Rolling Machine | 1 PC |

|